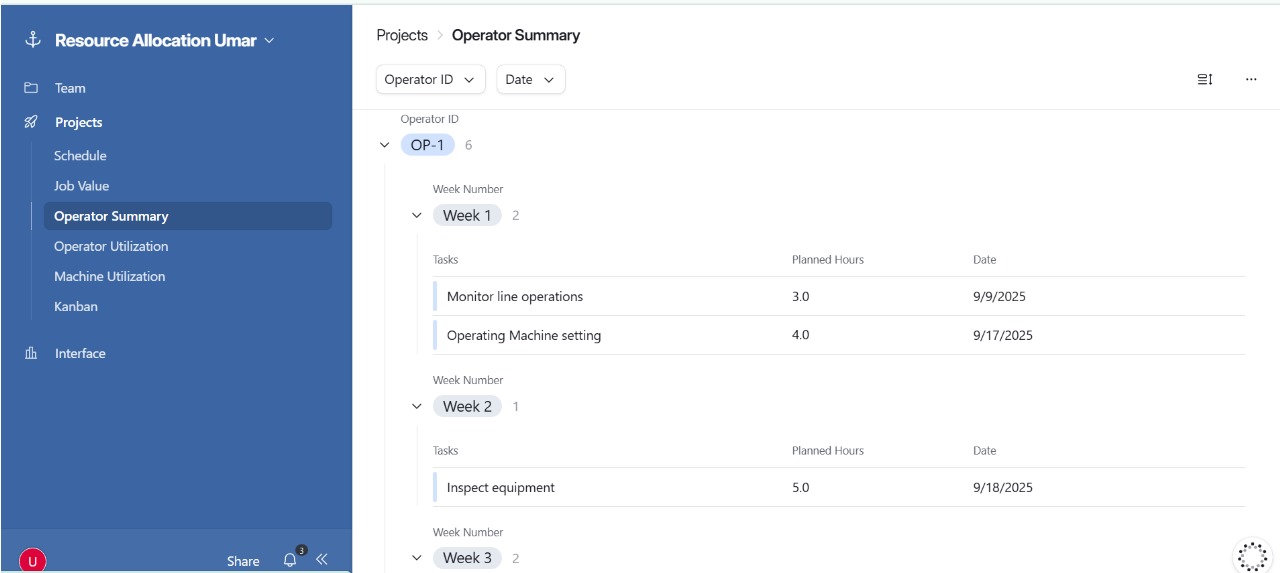

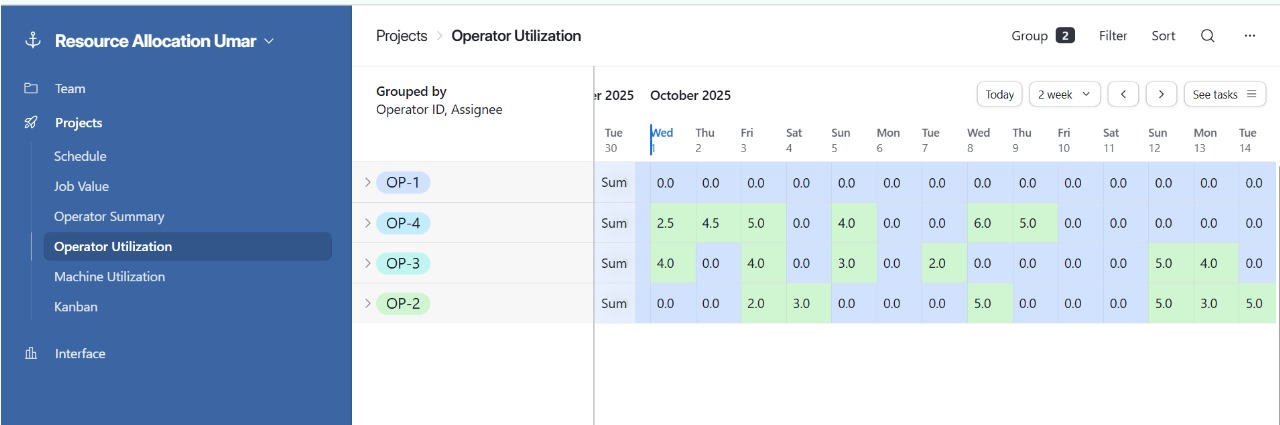

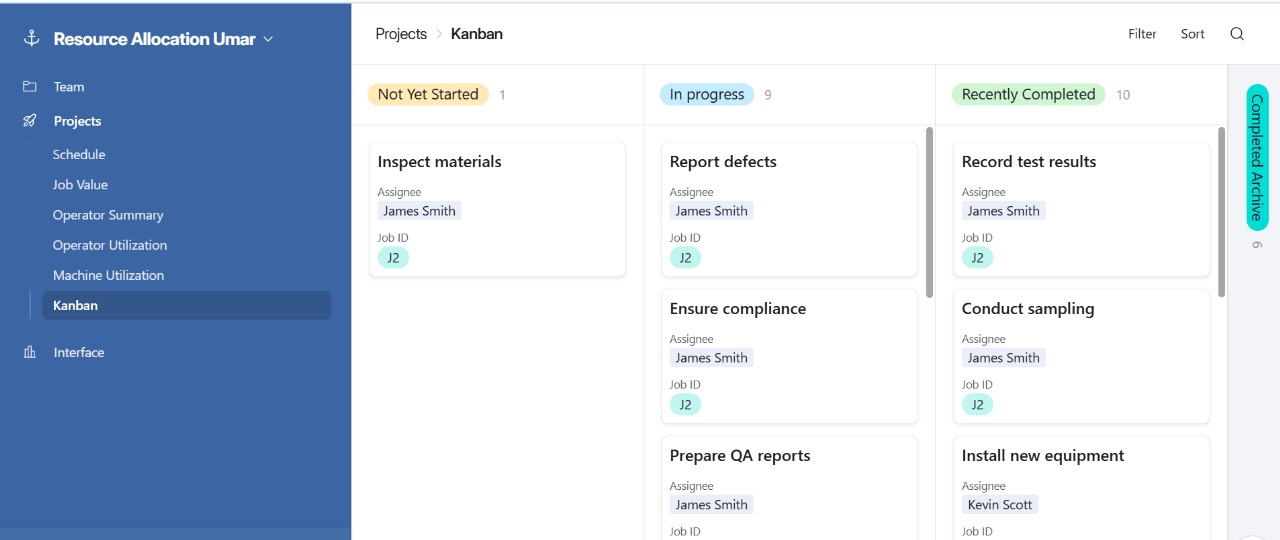

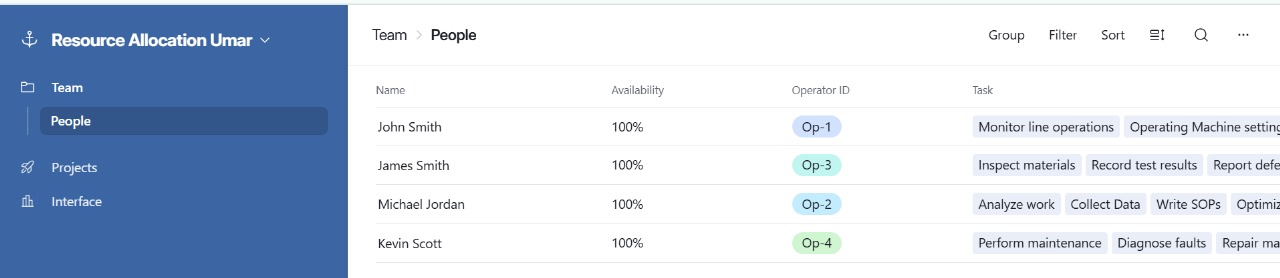

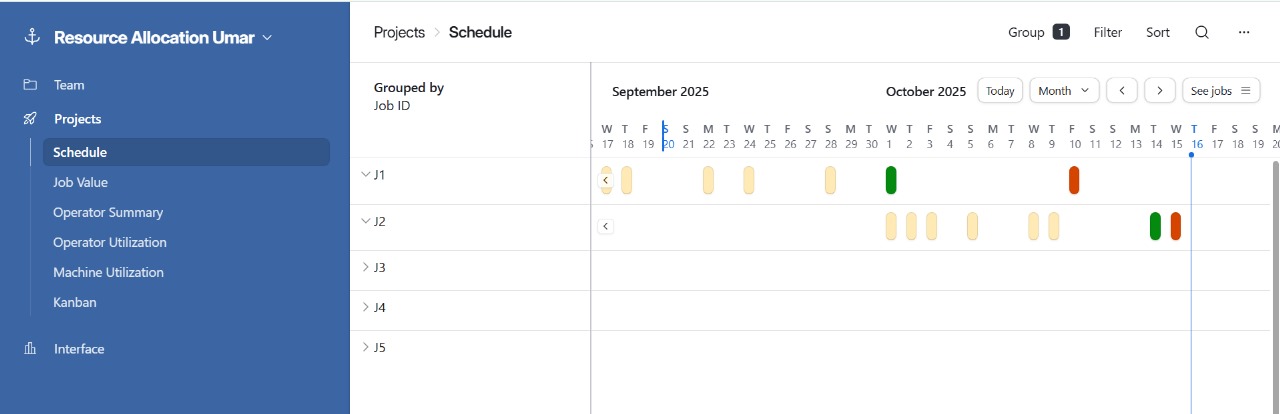

Real-Time Visibility

See every job, machine, and operator in one dashboard — no more guessing who's working on what or how long it takes.

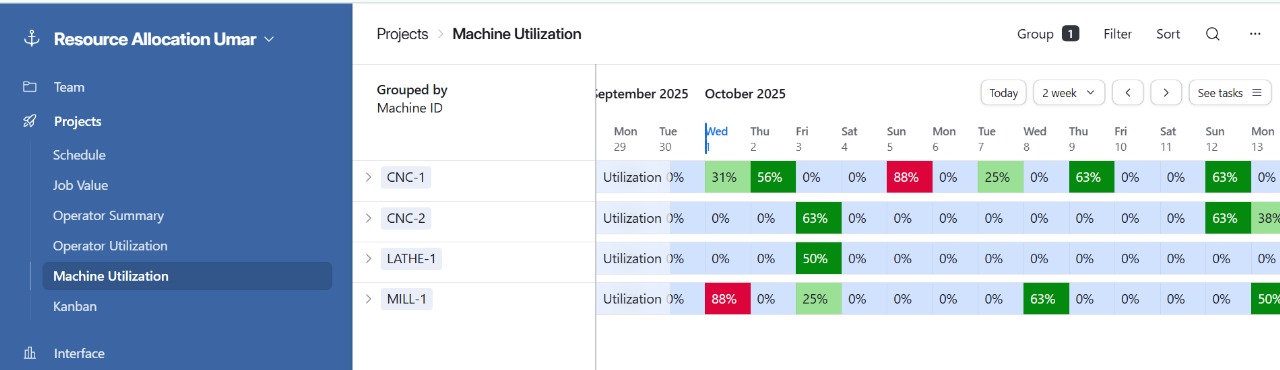

Increased Throughput

Identify bottlenecks early and keep machines running at peak efficiency to deliver more jobs with the same resources.

Fewer Delays & Downtime

Automated alerts flag idle time, tool changes, or late starts before they snowball into missed deadlines.

Smarter Scheduling

Balance workload across machines and operators with drag-and-drop scheduling and insights from each prior shift.

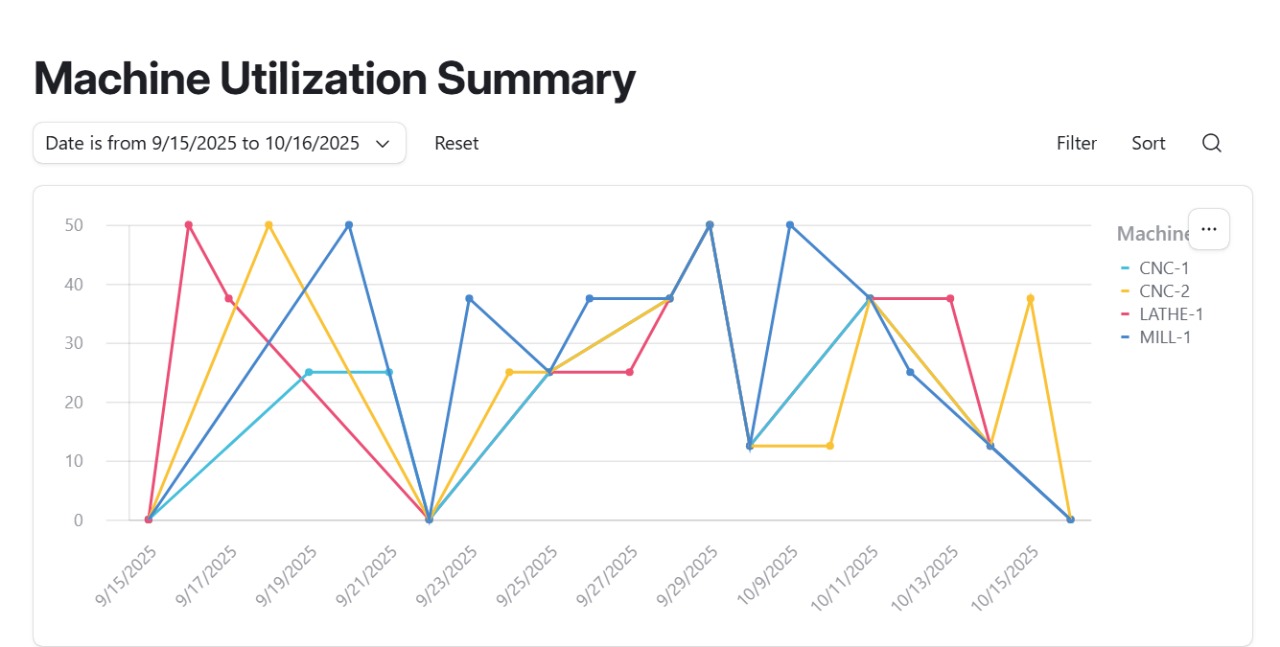

Data-Driven Decisions

Turn raw shop data into actionable insights — from cost scrap rates and setup times to on-time delivery trends.

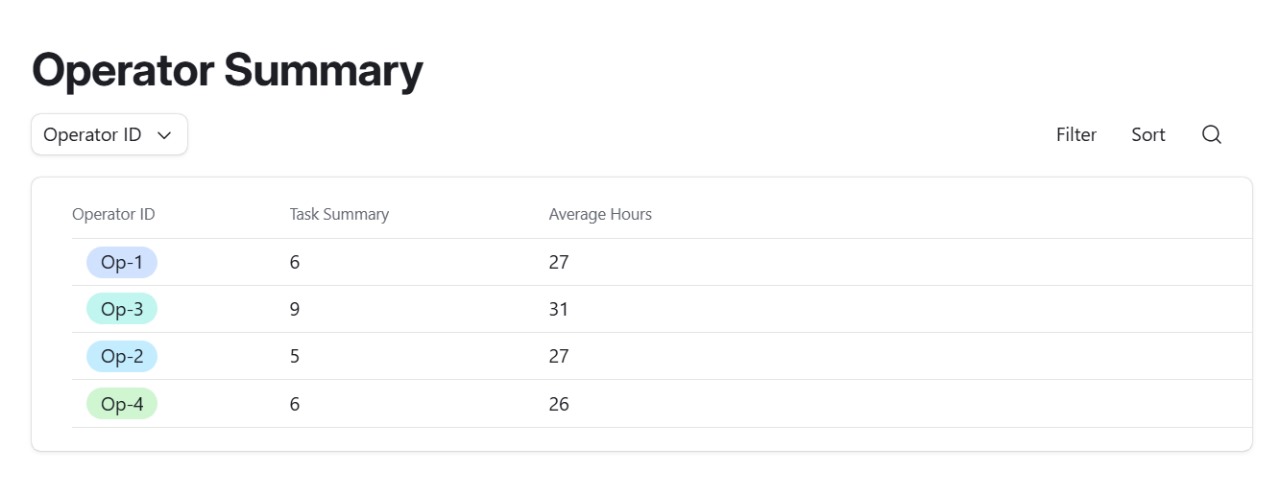

Operator Accountability

Track performance metrics by operator or shift. You can reward top performers and identify where extra training helps.

Streamlined Communication

Replace whiteboards, text chains, and sticky notes with live dashboards everyone can see — from the floor to the office.

Lower Operating Costs

Reduce rework, scrap, and machine idle time — saving thousands each month through improved process control.

Basic

Pro

Premium

Everything you need to know about MacDash

What does MacDash do?

Helps machine shops track machine utilization, job progress, and personnel performance in real time. Replaces outdated project tracking systems with live data, visual dashboards, and automated analytics.

How long does it take to get set up?

Most shops will be fully onboarded in 3-5 days. We guide you through initial setup, connect your machines or data sources, and personalize your dashboard views.

Do I need special hardware or IT staff?

No! Our team handles setup remotely, so you don't need any special hardware or in-house IT support.

How is MacDash different from big ERP systems?

Most ERP systems are powerful but slow, expensive, and overly complex for small and medium shops. MacDash gives you the same visibility and control without the enterprise price tag— it's affordable, flexible, and built for fast results.

Can I customize the dashboards?

Absolutely! Every account includes personalized dashboard customization.